What Should I do if an Appliance Fails a Pat Test?

By law, appliances and electrical systems need to be kept in a well maintained, safe condition ready for use. Whilst PAT testing your equipment is not compulsory within the laws and regulations, it is the most effective means of testing and maintaining electrical appliances. This is done in two stages; an initial visual check of the appliance to look for any outer damage such as exposed wiring or open casings – this can be done by anyone with sufficient knowledge and/or training or by a qualified electrical engineer – and is followed by an electrical inspection using a PAT testing device which checks the appliance for any internal electrical faults by analysing the current flow. This device will thoroughly check that the appliance has no ‘electrical leaks’ that could cause endangerment to users or damage to the immediate area around the appliance.

Failing a PAT Test

Appliances can fail a PAT test for numerous reasons, the most common of these being leakage from the Earth system within the appliance. This can lead to the appliance becoming ‘live’ to touch, making it very dangerous to handle and use. It is the responsibility of the appliance owner to ensure that equipment is safe for use. PAT testing is highly recommended as part of your regular maintenance routine and should be carried out at regular intervals throughout the lifespan of the appliance.

Appliances can fail a PAT test for numerous reasons, the most common of these being leakage from the Earth system within the appliance. This can lead to the appliance becoming ‘live’ to touch, making it very dangerous to handle and use. It is the responsibility of the appliance owner to ensure that equipment is safe for use. PAT testing is highly recommended as part of your regular maintenance routine and should be carried out at regular intervals throughout the lifespan of the appliance.

Should your appliance fail a test, it is essential that you receive a written explanation of the cause of failure so that you can then contact an electrical engineer who can repair the fault on the appliance – if your chosen test engineer cannot repair the appliance at the time of the test – and ensure that the appliance is once again safe to use. This engineer should then be able to re-test the equipment for you without the extra cost of another call-out to ensure that the appliance is use again safe for use.

If the appliance undergoing a PAT test produces readings outside of the ranges expected for the type of appliance, the PAT test will fail and the engineer performing the test will replace the ‘PAT Tested’ label with one informing users of a fault within the electrical system.

Until the fault is repaired or the appliance is replaced, it is strongly advised that the appliance is kept out of use and is properly labelled as faulty to prevent accidental use. Depending on the appliance and the designed purpose, use of faulty equipment can result in a serious injury or accident. Should this occur, the appliance owner can be held accountable for any injury or damage caused by use of the faulty item. In extreme cases, faulty electrical items can be a serious fire risk – either contained within the appliance or affecting the larger area surrounding the appliance.

For these reasons, despite not yet being required by law to have appliances PAT tested, it is strongly advised that you do so with all new and used equipment and that it is made part of a regular maintenance routine.

What a PAT Test Covers

The PAT test will check the appliance or system by analysing the current flow, measuring various resistances and performing a polarity check. The actual tests that your appliance will have run on it depend of the type of appliance. The main areas of the test are as follows;

An insulation resistance test which looks into the amount of electricity that is leaked from the appliance’s insulated wiring or external metal areas. This test must confirm that the appliance does not leak outside the expected ranges. Should the appliance leak higher than 5mA for class 1 appliances or 1mA for class 2 appliances, the test will be failed.

A polarity check on the plug or extension socket. This check is to ensure that the plug or socket has been properly wired and is not emitting a live charge.

An Earth continuity test to confirm that the appliance is not operating outside of the range provided by the appliance manufacturers. This is another test where the type of test done to measure this will depend on the type of appliance and can be tested using an ohmmeter or a PAT testing device.

And an Earth resistance test which makes sure that the earthing rods of the appliance are functioning correctly and within expected ranges.

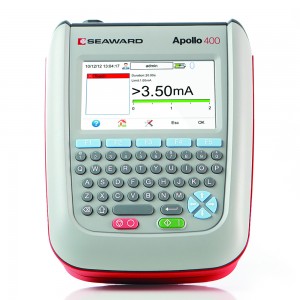

Appliances that include a RCD, ELCB or safety switch feature will also have this tested to ensure that the switch itself does not become a ‘live point’ on the appliance and that they operate within a specified range. Switch testing requires specialised test equipment, like the Seaward Apollo range, so it helps to inform your engineer of the need for this prior to the test being performed.

No comments yet. Be the first!